Condensate production in the Utica Shale’s volatile oil window in eastern Ohio has more than doubled over the past three years, and plans by the handful of E&Ps that focus on the super-light crude oil suggest that output will increase further this year and next. Who are these producers, why do they see such promise for condensate growth in the Utica, and how are they measuring their success? In today’s RBN blog, we continue examining rising condensate production in eastern Ohio with a look at the leading E&Ps in this space.

As we said in Part 1, the Marcellus/Utica region in Ohio, Pennsylvania and West Virginia is now one of the world’s most prolific and vital natural gas production areas, with output currently topping 35 Bcf/d and decades of reserves yet to be tapped. The overlapping shale plays generate hundreds of thousands of barrels of NGLs per day consumed in the Northeast and Midwest, piped or railed away to other U.S. and Canadian markets, or sent to the Marcus Hook or Repauno LPG export terminals near Philadelphia to be shipped overseas.

What’s less well-known is that parts of the Utica play (mostly in a few counties in eastern Ohio) also produce relatively modest amounts of crude oil, almost all condensate with an API value (or viscosity) of 55 to 59 degrees (and sometimes as high as 65 degrees). More recently, at least a couple of E&Ps in the Utica have been producing small volumes of heavy condensate with an API value closer to 50 degrees — still far lighter than West Texas Intermediate (WTI), which has an API of about 40 degrees.

Condensate production in eastern Ohio has been on a tear since the winter of 2021-22, topping more than 100 Mb/d in recent months. Pronouncements from the producers active in that slice of the Utica Shale indicate output could rise by tens of thousands of additional barrels per day — or maybe even double again, to past 200 Mb/d — in the next few years.

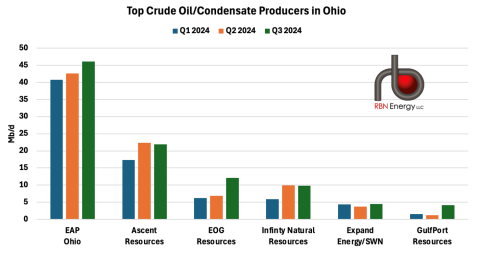

Figure 1. Top Crude Oil/Condensate Producers in Ohio.

Sources: Ohio Department of Natural Resources, RBN

Join Backstage Pass to Read Full Article