Over the past few years, tax credits and other incentives — both financial and regulatory — have breathed life into the U.S. market for sustainable aviation fuel, whose production is now ramping up, with more SAF capacity on the way. But the sector may experience turbulence under the incoming Trump administration, which has pledged to undo much of the Inflation Reduction Act (IRA) and pull back on the stepped-up decarbonization efforts that helped define the Biden presidency. In today’s RBN blog, we discuss the latest developments in the SAF space and the choppiness the still-fledgling sector may soon face.

As we said in Come Clean, jet fuel is the third-most-consumed transportation fuel in the U.S., accounting for about 10% of the total, and its high energy density — combined with the high reliability and efficiency of today’s jet engines — enables modern aircraft to fly long distances without refueling. We also said that, barring a major technological breakthrough in batteries or other alternatives, the most viable option to achieve significant reductions in greenhouse gas (GHG) emissions from the U.S. (and global) aviation industry is to replace an increasing share of the jet fuel consumed with SAF, which is chemically identical to conventional “jet” and can serve as a “drop-in” replacement for it. (Current rules generally limit the share of SAF in the jet fuel blend to 50% or less.)

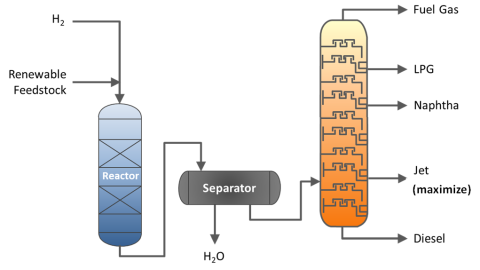

SAF and its cousin, renewable diesel (RD), are often produced at the same facilities, which makes sense given that similar processes and renewable feedstocks (vegetable oil, waste cooking oil, animal fats, etc.) are used to make them. At an RD/SAF refinery, those feedstocks are reacted with hydrogen (H2) at high pressure in a catalyst-filled reactor (blue step in Figure 1 flow diagram). After the reactor, the liquid hydrocarbons are separated from unreacted hydrogen and water (H2O; gray step), fed into a lower-pressure fractionation system and distilled into refinery intermediates (orange step). Note: Like conventional jet fuel, SAF needs to have a lower freeze point than RD (and conventional diesel) because of the very low temperatures jets encounter at high altitudes — that is typically achieved using a “de-waxing” catalyst in the reactor. (See Come Clean for more.)

RD/SAF Manufacturing Process Utilizing Hydrotreating Technology

Figure 1. RD/SAF Manufacturing Process Utilizing Hydrotreating Technology. Source: Baker & O’Brien

Join Backstage Pass to Read Full Article