Cushing has done it again! The all-important hub in central Oklahoma is once more broadening the range of crude oils it handles, this time by figuring out how to receive and blend the quirkiest of domestic oils: yellow wax crude from Utah’s Uinta Basin. Better still, the blending can create a fully compliant Domestic Sweet (DSW), the crude quality deliverable on the CME/NYMEX futures contract usually referenced as West Texas Intermediate (WTI). In today’s RBN blog, we discuss how it works and what it means for Uinta producers, waxy crude marketers, refiners and Cushing itself.

[Warning: This blog includes a not-so-subtle plug for RBN’s newly updated Cushing Playbook, a comprehensive explanation of the hub and its inner workings, who owns what, and how they use it all.]

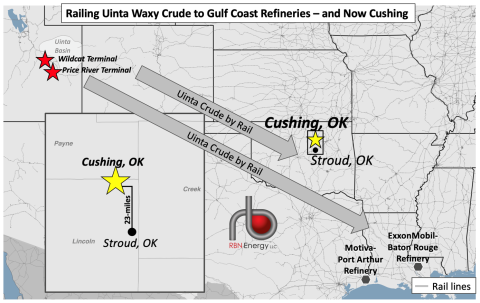

Production of the Uinta Basin’s medium-API-gravity, low-sulfur but super-waxy crude oil continues to rise — and now far exceeds the volumes Salt Lake City’s specially configured nearby refineries can use — but the high paraffin content of both the black and yellow varieties make them particularly challenging to transport and unload. Uinta E&Ps in northeastern Utah know the drill on local deliveries: Keep the stuff hot and in a liquid state, load it up hot into insulated tanker trucks and drive ‘em two and a half hours west/northwest to the five refineries in and around Salt Lake City. The same works for delivering Uinta waxy crude to the Wildcat and Price River truck-to-rail terminals (red stars in Figure 1 below) two hours south/southwest of the basin. Once it’s loaded into unit trains of rail tank cars there, waxy crude is railed down to a handful of refineries with the heated tankage and other specialized equipment needed to unload it, store it and blend it into the refineries‘ crude slates — and the fluid catalytic cracking (FCC) units that can break it down into desirable products.

The catch is, the five Salt Lake City-area refineries used to receiving waxy crude already are taking all the supplies they can handle and only a few refineries elsewhere — Motiva’s in Port Arthur, TX, and ExxonMobil’s in Baton Rouge among them (black dots in lower-right) — have the required equipment and heated storage needed to handle waxy crude. To put it simply, to support increased production, Uinta E&Ps need to find new demand.

Figure 1. Railing Uinta Waxy Crude to Gulf Coast Refineries — and Now Cushing. Source: RBN

Join Backstage Pass to Read Full Article