Crude-oil-focused wells in the Permian generate massive volumes of produced water, and E&Ps have made tremendous strides in dealing with it. Most important, a growing share of that water is being recycled for use in new well completions. But challenges remain. Deep disposal wells — a popular option for handling produced water — can spur seismic events, and shallow disposal wells can do the same and also negatively impact oil well integrity. As we discuss in today’s RBN blog, Permian E&Ps are taking an increasingly comprehensive, holistic approach to produced water management.

Produced water — that is, the briny, minerals-packed water that emerges from Permian and other wells with crude oil and associated gas — has been a frequent blog topic. As we said in our Wipe Out! blog series a few years back, in the olden days (before the Shale Era), E&Ps often dealt with produced water from old-school vertical wells by simply pumping it back into the same formation that it came from. That approach made the water disposal problem go away, and sometimes it actually improved well performance –– that additional water increased pressure at the bottom of the well and drove more oil into the well bore and up to the surface, hence initiating some of the first enhanced oil recovery (EOR) techniques.

But then shale happened. Horizontal drilling and hydraulic fracturing opens up previously impermeable rock for oil and associated gas (and produced water) to flow out — but not for produced water to flow back in. Instead, the produced water needs to be collected and dealt with. Through the first half of the 2010s, the volumes were relatively modest and were usually hauled off the lease in trucks to injection sites where it was pumped down deep, Class II “salt water disposal” wells (aka SWDs) drilled specifically for that purpose. As Permian production increased sharply later in the 2010s, so did produced water volumes. E&Ps and a handful of companies specializing in water-related infrastructure development and operation built out produced water gathering systems — pipelines that transported produced water from the lease to SWDs or (to a lesser extent at first) produced water recycling plants or specially built ponds where the water was left to evaporate. (See our Splish Splash blog series for more.)

A lot has happened since then — things that in total have taken the produced water part of the Permian production machine to a whole new level.

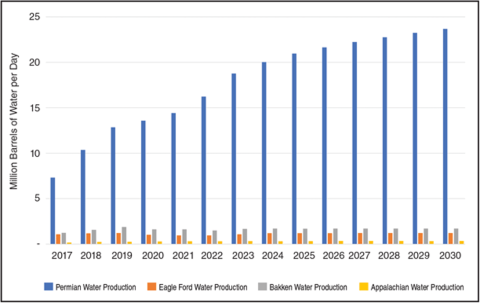

Before we dive into this, we should explain why we’re focusing on the Permian. To paraphrase Willie Sutton — who, when asked by a reporter why he robbed banks, replied “Because that’s where the money is” — the Permian is “where the produced water is.” As shown in Figure 1 below, crude-focused wells in West Texas and southeastern New Mexico (blue bars) account for the vast majority of the produced water generated in the leading U.S. shale plays. And produced water volumes in the Permian have been rising fast, from less than 8 MMb/d in 2017 to about 20 MMb/d this year to an estimated 24 MMb/d in 2030 — all according to our friends at B3 Insight. Those are extraordinary volumes — about 3.2 barrels of produced water for every barrel of crude, on average. And in some parts of the Permian the produced-water-to-crude ratio is as high as 12 to 1!

Produced Water Volumes by Shale Play, 2017-30

Figure 1. Produced Water Volumes by Shale Play, 2017-30. Source: B3 Insight

Join Backstage Pass to Read Full Article