In the past month we have written a couple of blogs describing the Mont Belvieu processing hub 30 miles east of Houston that is the center of the natural gas liquids (NGL) universe (see Can Mont Belvieu Handle the NGL Supply Surge Part I and Part II). Change is happening everywhere at Mont Belvieu in anticipation of about 300Mb/d of incremental Y-grade NGL supply flowing into the fractionation and storage hub from the burgeoning U.S. wet gas shale plays by the end of next year (2013). From all the NGLs that are processed in Mont Belvieu, some 30 percent ends up being distributed to end user markets as propane. Before that propane reaches Mont Belvieu it will likely have followed a long and winding road from where it was extracted from the ground in a wet gas production field. In today’s blog we trace a typical propane molecule’s journey to Belvieu.

Propane makes up roughly 30 percent of the NGL barrel. In April, the most recent month tracked by EIA, total U.S. propane production was 686 Mb/d. Somehow all that product needs to get to market. The road to that market is without a doubt, long and winding (thanks to Paul McCartney). Over the next couple of blogs we will travel that interesting and sometimes mysterious road with a molecule of propane. Our journey involves moving in and out of various facilities and accumulating costs each step of the way.

Our propane molecule can take many different roads to market but most likely will end up in Mont Belvieu. Over 70 percent of US NGLs currently flow through Mont Belvieu. Our representative molecule of propane begins its journey in the West Texas Permian Basin and ends up almost a thousand miles to the east on the Gulf Coast.

The Permian basin is one of the oldest crude, natural gas and NGL production basins in North America, covering a 250-mile-wide and 300-mile-long area in West Texas and southeastern New Mexico (see map below). Oil was first discovered in the basin back in 1920. Since then Permian has seen its fair share of booms and busts and by the late 1990’s was considered a mature, declining production area. Horizontal drilling techniques and the shale revolution have changed all that in the past few years and hotels in Midland and Odessa Texas are once again full of oil company representatives (this time dressed business casual). Our friends at Bentek forecast that by the second quarter of 2013 Permian Basin producers will be shipping as much as 400MB/d of incremental NGLs across Texas from the Permian Basin to Mont Belvieu via the planned Texas Express and Sand Hills pipelines.

Today we’ll track our propane molecule on existing assets. In our story, the propane molecule comes out of the ground at a Pioneer Resources production well in the Sprayberry field in the heart of the Permian Basin. Pioneer is one of the largest acreage holders, drillers and producers in the Permian.

Production and Lease Processing

Our propane molecule comes out of the ground as part of a wet (high BTU) gas stream from one of Pioneer’s drilling leases in Upton County, TX. The molecule reaches the surface along with a mixture of other hydrocarbons and impurities. Note that our use of the word ‘wet’ here has nothing to do with water content.

Once at the surface, our molecule heads directly to its first encounter with processing at the drilling lease location. This first processing experience includes encounters with an assortment of separators, dehydrators and amine units designed to remove unwanted impurities such as water, sulfur, helium, nitrogen and carbon dioxide. Kind of like an hour at the confessional.

Gathering and Chillin’ – Getting Ready for Pipeline Time

Like the confessional, initial processing can’t remove all the impurities – only those that can be easily extracted. After initial processing our propane molecule is still bundled together in the wet gas with all the other remaining hydrocarbon molecules including methane (natural gas) and the other NGL’s namely: ethane, normal butane, isobutane, and natural gasoline. This wet gas is now ready to head to a local natural gas processing plant via a “gathering” pipeline system. Gathering systems are small (narrow diameter) pipelines that pick up similar hydrocarbons in the lease area for transport to processing. In our case, the propane molecule is headed to the Midkiff/Benedum processing facility, which is also located in Upton County. Pioneer owns 27 percent of this particular processing plant and utilizes more than 40 percent of its capacity to process their own wet gas production.

We are not going to dwell on our molecule’s ownership as we follow its journey but rather refer to changes in its custody along the way. Custody changes at the processing plant from the producer to the midstream plant operator that extracts NGLs from the wet gas and transports them to a fractionation plant. In our case, the processing plant operator (in this case the majority owner of Midkiff/Benedum – Atlas Pipeline Partners) takes a 16 percent cut of the residue gas (i.e. the dry natural gas that is left after removing liquids) as a processing fee and then pays Pioneer the value of the NGLs that are extracted from the wet gas (based on some revenue and cost formula in the agreement). As we learned in “The Golden Age of Natural Gas Processors – NGLs in a 50X Crude to Gas Ratio World Part III” these processing agreements vary quite widely in their terms – in this case Pioneer is receiving all of the uplift for NGLs from their wet gas and that is a favorable deal since NGL values are currently significantly higher than the dry natural gas. Whatever the processing agreement, the actual processing is the same.

Things get very chilly when our molecule hits the Midkiff/Benedum processing facility. In fact the temperature gets down to negative 120 degrees Fahrenheit so that the NGL portion of the wet gas turns to liquid. At this point the residue methane gas is ready to flow onto a natural gas pipeline. The separated NGL’s will be going another direction, starting on their long journey to Mont Belvieu.

Long Pipeline Journey to Mont Belvieu

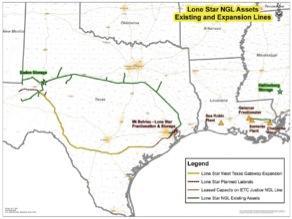

Our propane and all its fellow NGL molecules are now part of a mixed stream called y-grade (see “Can Mont Belvieu Handle the NGL Supply Surge? – Part II” to learn more about y-grade). The processing thus far has ensured that our molecule meets pipeline y-grade product specifications. The long journey across Texas to Mont Belvieu is going to take place, appropriately enough, on the Lone Star Pipeline that connects with the Midkiff/Benedum processing facility. On the pipeline map (below) you can see two Lone Star pipelines linking the Permian Basin with Mont Belvieu. Our propane molecule will travel on the green route going due west toward Dallas before turning south toward Houston. The yellow route to the south is a Barnett Shale area expansion project scheduled to be ready in 2013. The 1000 mile journey on Lone Star will cost about $.11/gallon or $4.7257 a barrel (based on Lone Star’s published tariff).

In the Permian Basin and along the way to Mont Belvieu, the Lone Star Pipeline has more than 20 other receipt points besides Midkiff/Benedum. All of them are gas processing plants delivering similar y-grade streams, each joining our molecule as we make the trip to Mont Belvieu. In fact, ours could be one molecule of as many as 144 MB/d barrels travelling this path.

That’s as far as we will take our Propane molecule today. In tomorrow’s installment we will trace the path of our propane molecule at Mont Belvieu through storage, fractionation, storage as an end use product, and distribution to an end user.

Each business day RBN Energy posts a Blog or Markets entry covering some aspect of energy market behavior. Receive the morning RBN Energy email by simply providing your email address – click here. |