The oil and gas industry is always working to develop the most efficient methods for unlocking more hydrocarbons. To cut costs and maximize output from their acreage, some companies are rolling out more creative well designs, such as U-turn (aka “horseshoe”) and J-hook wells, which use dramatic, 180-degree underground turns to access more oil and gas from each location. In today’s RBN blog, we’ll discuss the benefits of these approaches and the technical hurdles associated with drilling these deep bends underground.

In Part 1 of this blog series, we discussed how the Shale Era was made possible by unprecedented advancements in drilling and completion technology, especially in horizontal drilling and hydraulic fracturing. The combination of the two, along with other basin-specific techniques, has significantly increased the efficiency of oil and gas recovery, as evidenced by, among many things, higher initial production (IP) rates, lower decline rates and higher EURs (estimated ultimate recovery numbers). We also detailed how the industry has increasingly utilized much longer laterals and how the choice of well tubing — coiled or stick pipe — plays an important role.

At the beginning of the drilling process, a crucial decision must be made regarding how the well will be designed. Typically, in horizontal drilling, it starts by drilling a vertical section from the surface down to the targeted rock formation. Then, the directional drilling will steer the wellbore into a horizontal path, which can extend for one, two or three miles, and even longer in some cases. This can increase the amount of hydrocarbons that can flow into the well and boost production rates. Once the well is at the desired depth, the wellbore is lined with steel casing and cemented in place to prevent collapse. Then, the well is hydraulically fractured, and finally, pumps are installed to bring oil or gas to the surface.

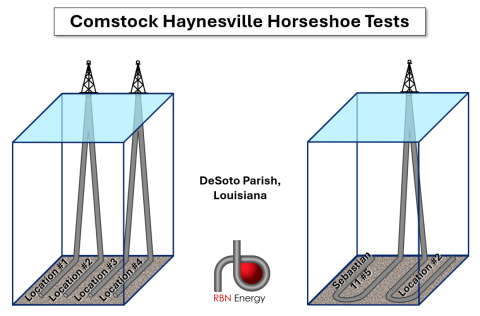

While the horizontal well is the go-to design in most popular shales in the U.S., a few E&Ps have started pushing boundaries in the last few years with new twists on the horizontal well design. The first we’ll discuss is the U-turn or horseshoe well. This is a more complex technique often used where space is tight, or the geology is challenging (more on that below). It starts with the drill path going down vertically from the surface, just like a typical horizontal well. Once it reaches the target depth, it turns and drills horizontally, usually about a mile out. Here’s where the twist comes in. Rather than stopping or branching straight out, the drill bit makes a tight 180-degree or U-turn underground and heads back in the opposite direction. This creates a second horizontal leg parallel to the first, as shown in the graphic to the right in Figure 1 below.

Figure 1. Comstock Haynesville Horseshoe Test. Source: Comstock

Join Backstage Pass to Read Full Article