The refining industry is complex and unpredictable. Recent plant closures in the U.S. and abroad, as well as mounting pressure to produce more renewable diesel (RD) and sustainable aviation fuel (SAF), have shifted the landscape. In addition, an eight-year battle over CITGO’s three U.S. refineries has taken a new direction. Despite these shifts, the refining industry has remained resilient. In today’s RBN blog, we’ll discuss how refineries balance these changes and make choices to shape their future, the focus of our upcoming Refined Fuels Master Class. Warning: Today’s blog is a blatant advertorial.

As we discussed in Us and Them, the U.S. refining industry has undergone a number of changes in recent years, and more turbulence is likely as global economic and trade patterns shift and many governments push decarbonization efforts. For some U.S. refineries, this has led to closures due to weak profits, rising regulatory costs and declining demand for products, particularly gasoline. But other refineries have prospered and even invested in expansions. The domestic refining industry has evolved into the most competitive in the world, and the issues and challenges faced by other countries will likely benefit U.S. refiners.

In today’s blog, we’ll discuss refining basics, the latest news with the CITGO refineries, the push to increase RD and SAF production, and the importance of using the crack spread and yield models to analyze refining margins. Those are among the topics to be covered in greater detail during our upcoming Refined Fuels Master Class, an online-only event hosted on Thursday, October 2, from RBN’s Refined Fuels Analytics (RFA) practice.

Refining 101

We begin by ensuring understanding of the refining process. Refineries are dynamic hubs that can stretch over thousands of acres, employ more than 2,000 people and often operate at 90% capacity or higher to transform crude oil into fuels like gasoline, diesel and jet fuel. Each refinery is unique and can adjust the quantity of the products it produces depending on market demand and the type of crude oil processed.

The process is quite complex. There’s a mix of separation, conversion and treating processes that happen behind the scenes inside pipes, towers and reactors. The key steps include distillation, which separates crude oil into different fractions; and cracking and reforming, where heavy molecules are broken down or improved. Hydrocrackers boost jet and diesel production while reformers increase gasoline octane and generate hydrogen. Hydrotreaters play a crucial role in removing sulfur, making products cleaner and more environmentally friendly.

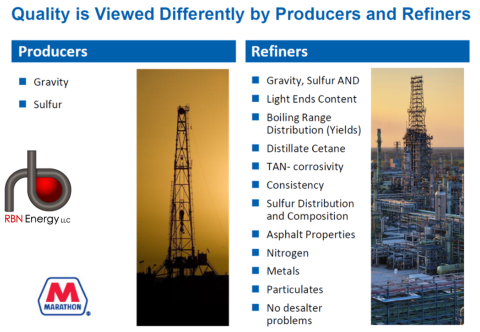

Figure 1. Quality is Viewed Differently by Producers and Refiners. Source: RBN

Join Backstage Pass to Read Full Article